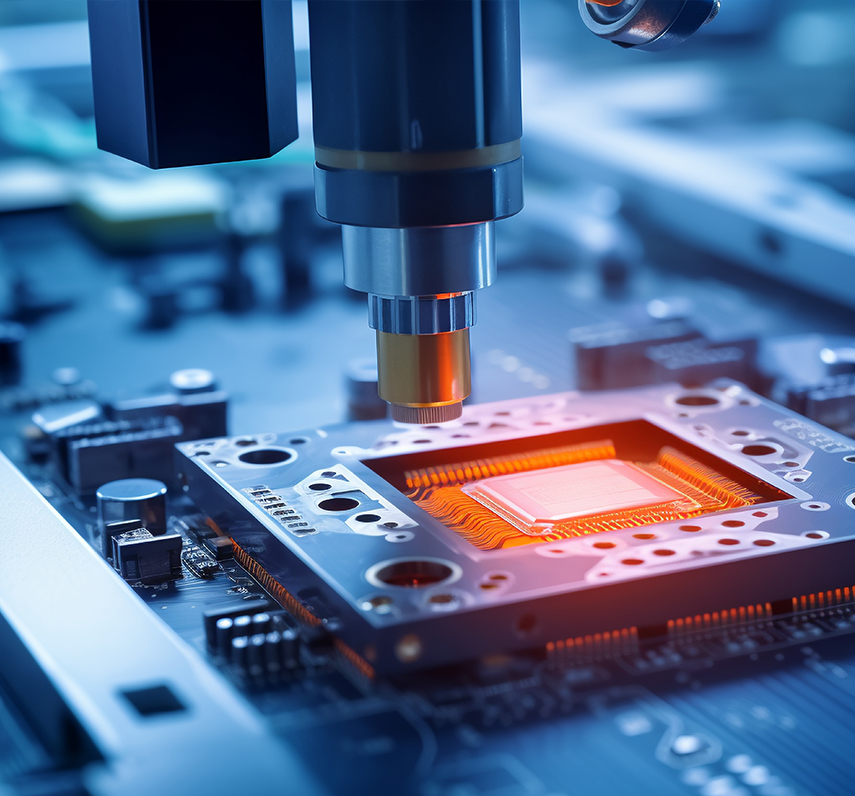

MEMS stands for Micro-Electro-Mechanical Systems. The Piezo MEMS Silicon Solutions leverage the inverse piezoelectric effect, where an input voltage causes piezo MEMS materials to contract or expand, transforming electrical energy into mechanical energy. This mechanical energy drives an integrated membrane, producing airflow and pressure essential for sound generation. This approach enables more precise, reliable, and energy-efficient audio and sensing solutions, marking a new frontier for next-generation acoustic products. Key applications of MEMS acoustic products include wearable devices, medical instruments, and consumer electronics.